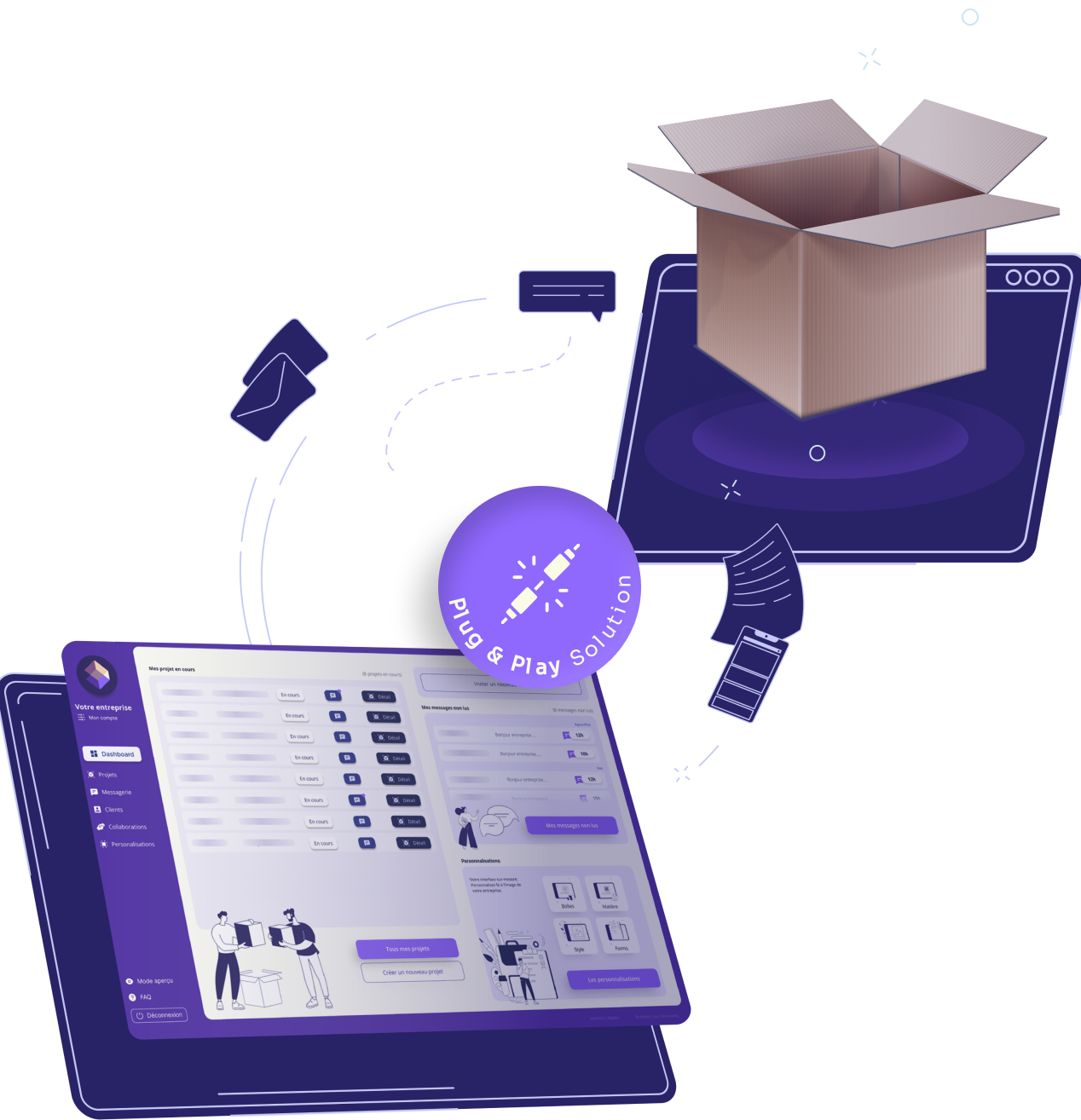

Sellcustomized boxes

through yourown website

Boxtailors offers your customers direct web access toyour solutions. To reassure you and facilitate your customer relation.

Bring value addedsolutions to your customers through small batch boxes

Start selling online now

Plug & Play web configurator

Your own branding

Affordable solution

Simplify your quote process

Collect customer requirements online

Save your technical department time

Focus on value added designs and tasks

Improve Customer Experiences

Deliver quotes quicker

Customers see what they get in 2D/3D

Ordering process guide

A simple interface for your relationships with your customers

Plans to fit your scale

Essential

Boxtailors with your branding

3D Configurator

Project Management Tool

169 € user/month

Billed annually

Premium

All Essential features

Design & Print Management

Easy Pricing Tool

499 € company/month

2000 € Set up fee

Billed annually

Custom

All Premium features

Your own e-commerce site

Contact us

0

Latest news and updates

Is Cardboard Eco-Friendly ?

Unveiling the Truth Behind Cardboard’s Environmental Impact Cardboard, the unsung hero of packaging, often raises questions about its eco-friendliness. Let’s embark on a journey to explore the sustainability of this humble material and decipher its environmental footprint. The Lifecycle of Cardboard: From Forest to Factory 🔄 Sustainable Sourcing: Cardboard production begins with responsibly sourced materials. Trees are harvested from managed forests, ensuring minimal environmental impact and promoting biodiversity. 🌳 Efficient Manufacturing: The manufacturing process involves pulping recycled paper fibers, significantly reducing the strain on natural resources. Advanced technologies further enhance efficiency, minimizing energy consumption and carbon emissions. ♻️ Environmental Impact Analysis 📊 Biodegradability and Recyclability: Cardboard’s biodegradability and recyclability are key factors in its eco-friendliness. When disposed of properly, cardboard decomposes naturally, returning nutrients to the soil. Additionally, cardboard can be recycled, reducing waste and conserving resources. ♻️ Quantifying the Impact : production of 1 ton of recycled board 1.2 tonnes of used paper and cardboard: Producing 1 tonne of recycled cardboard generates 1.2 tonnes of used paper and cardboard, resulting in 200 kg of waste. 56 kg of chemicals: Approximately 56 kg of chemicals are used in the pulping process, with 90% being recycled. 70,000 L of water: Water usage in cardboard production amounts to 70,000 liters per tonne. While some is recycled within the facility, the remainder is treated before returning to nature. 2500 kW/h of energy: The production process consumes around 2500 kW/h of energy, sourced from electricity or gas. Debunking Common Misconceptions 🛑 Myth: Cardboard is Harmful to the Environment: Contrary to popular belief, cardboard production is relatively eco-friendly. With proper recycling and waste management practices, its environmental impact can be minimized. Myth: Cardboard Contributes to Deforestation: Sustainable forestry practices ensure that cardboard production does not deplete forests. Responsible sourcing and replanting initiatives contribute to forest regeneration and biodiversity preservation. Embracing Sustainable Solutions 🌟 As consumers and businesses increasingly prioritize sustainability, cardboard remains a versatile and eco-friendly packaging option. By choosing cardboard products and supporting recycling initiatives, we contribute to a greener future for generations to come. 🌍 Join the Movement 🌱 Ready to make a difference? Explore sustainable solutions with Boxtailors, your partner in digitalizing customer relations for cardboard transformers. For cutting-edge machinery tailored to your cardboard processing needs, discover Mécanélec. Together, let’s champion sustainability and pave the way for a brighter, greener tomorrow. ♻️ In conclusion, cardboard emerges as a sustainable packaging solution with its biodegradability, recyclability, and minimal environmental footprint. By dispelling myths and embracing eco-friendly practices, we can harness the power of cardboard to create a more sustainable world. 🌱